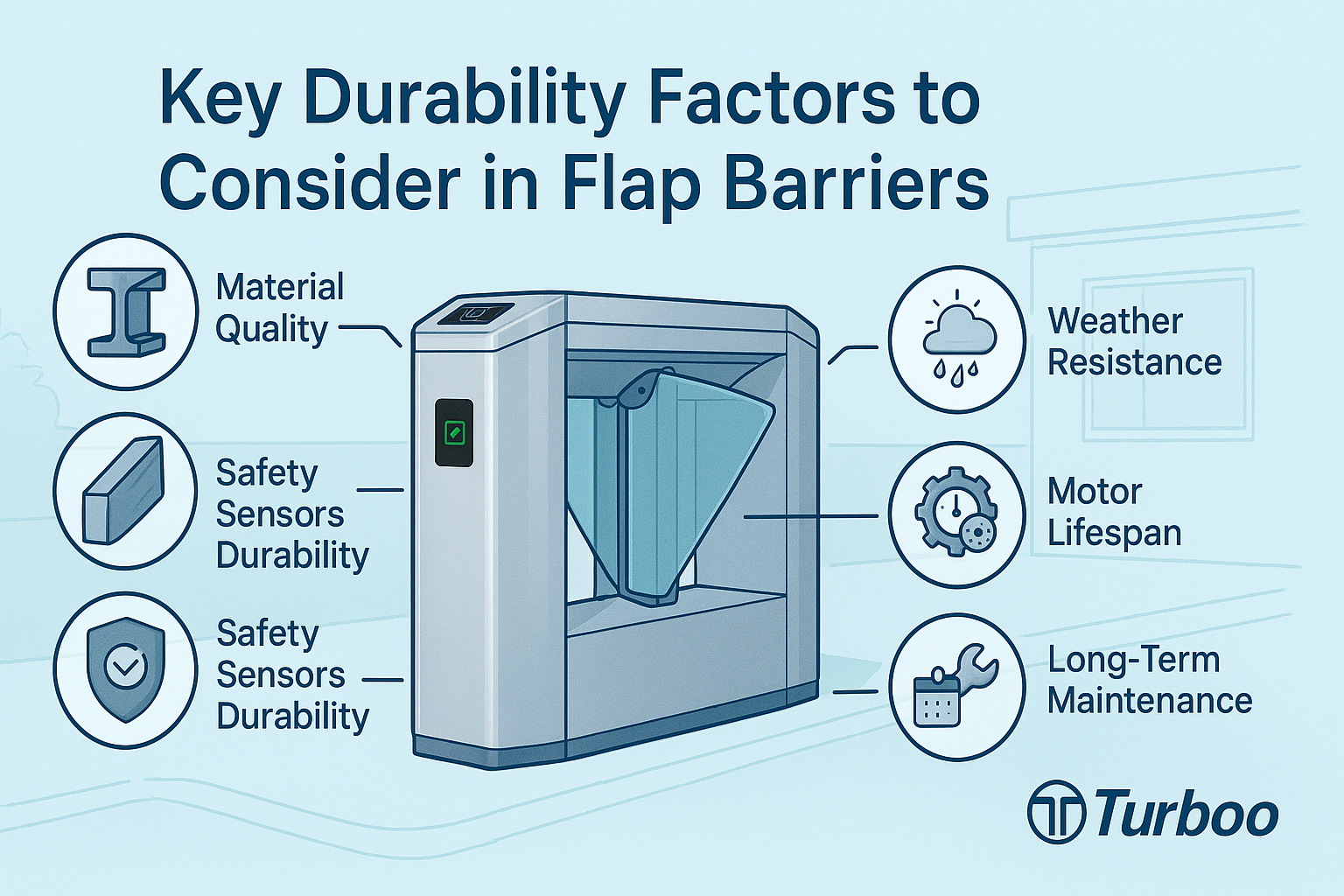

Key Durability Factors to Consider in Flap Barriers

When you’re choosing a flap barrier, durability should be the first thing on your checklist. That’s because a weak or poorly made barrier doesn’t just wear out fast—it creates constant problems. Think about it: every breakdown means downtime, expensive repairs, and unhappy users. And in critical locations like corporate buildings or train stations, you can’t afford those delays.

A strong, well-built flap barrier lasts for years. It performs consistently. It resists damage, works in tough weather, and keeps functioning smoothly even in high-traffic environments. That’s what long-term performance really means. It’s not about looking good on day one—it’s about performing day after day, with minimal maintenance and maximum uptime.

Yet many buyers get distracted by flashy features or low prices. They overlook the barrier’s structural build, material strength, or resistance to daily wear. The result? A system that starts off fine but quickly becomes a liability. Choosing durable materials and components from the start can save you thousands over the life of the product.

This article walks you through all the key durability factors. You’ll learn what to look for, what specs matter, and how to match your flap barrier to your environment. Whether you’re managing a public facility, a secure campus, or a commercial complex, this guide will help you make a purchase that truly lasts.

Material Type and Thickness

Material strength is the foundation of flap barrier durability. It determines how well the system stands up to physical impact, environmental stress, and daily wear. In most high-quality barriers, you’ll find materials like 304 or 316 stainless steel. These are not just industry favorites—they’re the gold standard for toughness, corrosion resistance, and visual appeal.

304 stainless steel is great for indoor or semi-covered areas. It’s strong, resists rust, and handles the occasional bump or scratch. 316 stainless steel is the upgrade. It has added molybdenum, which makes it even more resistant to chemicals and salt. This is perfect for coastal regions, outdoor spaces, or industrial zones with harsh air quality.

Some barriers also use aluminum alloys, especially where weight reduction is a priority. Aluminum is still quite strong and adds a clean, modern look. It’s also naturally corrosion-resistant, though it can dent more easily under strong impact.

Thickness matters just as much as material type. Thin metal may look sleek, but it bends, warps, or cracks under pressure. For maximum durability, the frame and flaps should have sufficient thickness—usually 1.5mm to 2mm for stainless steel. This allows the structure to withstand daily use, sudden impact, and tampering attempts.

You can explore more on this by reviewing the breakdown of flap barrier materials. Understanding the materials behind the design helps you predict how long the product will hold up and how often it will need maintenance or part replacements.

So before you buy, ask your vendor exactly what materials are used—and how thick they are. That one detail tells you more about a barrier’s durability than most marketing claims ever could.

Corrosion Resistance for Outdoor and Harsh Environments

Corrosion is one of the biggest threats to flap barrier durability. When metals are exposed to moisture, salt, or harsh chemicals, they begin to degrade. Rust forms. Joints weaken. Moving parts jam. Eventually, the whole system breaks down. That’s why corrosion resistance isn’t optional—it’s a must-have, especially for outdoor or semi-exposed installations.

The level of corrosion resistance depends on the metal composition and protective finishes. Stainless steel is the top performer here. As mentioned earlier, 316 stainless steel offers superior corrosion resistance thanks to its molybdenum content. It performs well in salty air, humid climates, and industrial zones where airborne chemicals are common.

In some cases, powder-coated finishes or anodized aluminum can be used to add extra layers of protection. These treatments seal the surface, preventing moisture from reaching the metal underneath. They also improve aesthetics by offering a clean, scratch-resistant exterior.

Why does this matter so much? Because outdoor barriers face more than just rain. UV exposure, sudden temperature changes, and pollution all wear down unprotected surfaces. Once corrosion starts, it spreads. It can even affect internal components like motors or sensors if the barrier isn’t properly sealed.

To avoid this, always check the corrosion resistance ratings or material standards before purchasing. You can verify compliance through certifications or references to ASTM standards, which set benchmarks for material quality. Visit the ASTM site for a better understanding of material grades used in security equipment.

Choosing corrosion-resistant barriers means fewer repairs, better appearance, and longer operational life. It’s a simple decision that pays off for years.

Motor Lifespan and Performance

The motor is the heart of any flap barrier. It controls the opening and closing motion. It runs every time someone enters or exits. If the motor isn’t built to last, the whole system fails—no matter how strong the exterior looks.

Durable barriers use brushless DC motors. These are quiet, efficient, and long-lasting. They have fewer moving parts than traditional brushed motors, which means less friction and less wear. That translates to a longer lifespan—often measured in millions of cycles. A high-quality motor can last for five to ten years under regular use.

Another factor is thermal protection. Good motors are built to handle continuous operation without overheating. They include sensors that shut the motor down temporarily if it gets too hot, protecting it from burnout. In hot climates or high-traffic areas, this feature is essential.

You should also look at cycle ratings. This tells you how many open-close operations the motor can perform before needing replacement. Standard models may offer 2 to 3 million cycles. Industrial-grade systems can go beyond 10 million. These figures give you a rough idea of expected service life—and what kind of maintenance schedule you’ll need.

Flap barrier performance depends heavily on this core component. You can explore system performance benchmarks and comparisons in this flap barrier performance guide. It outlines how motor efficiency links directly to speed, power consumption, and long-term cost.

Always ask vendors for motor specs, cycle test results, and warranty terms. If a barrier has a strong motor, it’s much more likely to serve you well for the long haul.

Mechanical Strength and Structural Stability

Flap barrier durability depends heavily on the internal frame and how the components are structured. Even the best materials won’t matter if the internal design is weak or poorly reinforced. Mechanical strength determines how well the barrier handles repeated use, accidental impact, or even intentional abuse.

A strong barrier should be able to absorb everyday force without bending, cracking, or misaligning. This includes physical pressure from crowds, rolling luggage, or cleaning equipment. Inside, the frame should use reinforced joints and welded connections to maintain alignment and avoid loosening over time.

The mechanical parts, like the flap arms, gears, and support brackets, must also be built to last. High-stress points such as the hinge of the flap or the track that guides its movement are especially vulnerable. If these wear down quickly, the barrier will start to wobble or jam—two signs that the mechanical strength is failing.

For barriers used in public transport, stadiums, or busy buildings, this issue becomes even more important. Hundreds or thousands of users per day means constant movement and friction. Only barriers with high mechanical strength can keep up without breaking down.

Structural stability also affects the unit’s resistance to tampering or forced entry. If someone tries to push through without authorization, the barrier must remain secure. Weak structures might deform or even allow access, defeating the entire purpose of access control.

During the purchasing process, ask about impact resistance testing. Reputable manufacturers perform force simulations to ensure the barrier can hold up to physical stress. You can also read more about product validation methods at UL’s durability testing page. These standards are designed to help facility managers understand which products are built to endure.

Environmental Protection Ratings

Environmental protection plays a huge role in flap barrier durability. Whether your barrier is indoors or outdoors, it will still face exposure to elements like dust, moisture, and temperature shifts. These conditions can damage sensitive components, reduce lifespan, or cause sudden malfunctions if the barrier isn’t properly sealed and rated.

The best way to assess environmental protection is through IP ratings—short for Ingress Protection. These two-digit codes indicate how well the system resists solid particles and liquids. For example, an IP54 rating offers limited protection from dust and splashing water. It’s fine for indoor environments but not ideal for heavy exposure. On the other hand, an IP65-rated barrier can handle full dust ingress and strong water jets—perfect for outdoor installations.

IP ratings are part of standard flap barrier specifications, and they’re essential for choosing the right product for your location. Dust and water might not seem dangerous, but they can block sensors, corrode metal, or short out control boards. Even air humidity can damage unprotected electronics over time.

That’s why weather sealing is a must. Good barriers use rubber gaskets, waterproof housing, and sealed connectors to keep out moisture and debris. The flaps themselves should also be designed to shed water and resist rust. If you’re in a region with seasonal storms or frequent cleaning cycles, this matters even more.

Temperature resistance is another key consideration. Most flap barriers can operate from -10°C to 60°C. However, extreme climates may require built-in heaters or cooling fans to protect internal systems. If you plan to install the barrier in a parking garage, exterior lobby, or industrial site, check the temperature and humidity specs carefully.

Matching the environmental rating to your installation location helps prevent breakdowns and service calls. It’s a basic requirement that’s easy to overlook—but it can save you years of trouble and hundreds in repair costs.

Wear Resistance in High-Traffic Installations

Wear and tear is unavoidable in flap barrier systems, especially in areas with high foot traffic. However, how the system handles that wear is what separates a reliable barrier from one that constantly breaks down. That’s why wear resistance is a core part of flap barrier durability.

Every opening and closing cycle causes a small amount of mechanical wear. Over time, this adds up. The most vulnerable parts are the flaps, hinges, bearings, and the tracks or arms that guide motion. If these components are made from soft or low-grade materials, they’ll degrade quickly. That leads to flaps that don’t align, motors that strain, and systems that shut down.

Durable barriers use wear-resistant polymers, self-lubricating bearings, and reinforced hinges to reduce this wear. These components are designed to handle millions of cycles without losing precision or smoothness. Some models even include smart sensors that detect performance dips before failure happens.

This kind of technology is especially important in locations like subway entrances, airport gates, or university campuses. In these places, the barrier must function continuously throughout the day without missing a beat. If the system wears out quickly, not only does it stop working—it creates entry delays, safety issues, and more maintenance work.

Barrier design also affects wear resistance. Systems with fewer moving parts or enclosed mechanisms tend to last longer because there are fewer areas where dust and friction can build up. Regular use won’t degrade them as fast, which translates into lower maintenance costs and higher reliability.

When reviewing a barrier’s specs, ask about cycle life, replacement part intervals, and wear-resistant design features. Products built for high-traffic areas will usually have this information readily available. If they don’t, that’s a red flag.

Quality Control and Testing Protocols

Flap barrier durability doesn’t just depend on the design—it also hinges on the quality control practices during manufacturing. Even with the right materials and engineering, a poorly built barrier won’t last. That’s why it’s crucial to understand the testing protocols and quality checks that back up the product.

Manufacturers who prioritize durability will conduct real-world durability tests. These tests simulate years of usage in a compressed timeline. Flap barriers are cycled open and closed hundreds of thousands of times to test fatigue. They’re exposed to dust, moisture, vibration, and even impact to ensure that parts won’t degrade or loosen under stress. These stress tests verify the product’s long-term performance, not just its showroom appeal.

There are also international standards that manufacturers can follow to ensure consistency and reliability. These standards often come from organizations like UL, which provides independent product testing, or UL durability certifications, which verify how products perform under stress. Compliance with such protocols is a mark of serious quality.

Material consistency also matters. Some barriers fail early because their metal is substandard or their motor components are not properly aligned. Quality checks at every stage—cutting, welding, assembling, and final calibration—are necessary to prevent such issues. High-end suppliers will have in-house inspection teams that verify these standards.

For buyers, the presence of a robust quality assurance process is a strong signal that the product is built to last. Ask your vendor about the factory’s testing procedures. Request sample test results or certifications. If a company avoids the topic or lacks proof of rigorous testing, you’re taking a risk.

Durability doesn’t come from guesswork. It comes from tested, verified production lines where each unit is measured against strict benchmarks. When these systems are in place, you get fewer defects, better consistency, and far less chance of early failure.

Installation Impact on Barrier Longevity

Installation is the first point where even the best flap barrier can go wrong. If the barrier isn’t set up correctly, its components can misalign, overstrain, or wear out faster. That’s why the way you install your flap barrier has a direct impact on its lifespan and ongoing durability.

The ground needs to be level and solid. Flap barriers rely on perfect alignment between the flap mechanism and the base frame. If the surface isn’t even, the flaps may drag, the motor may strain, and the sensors could misfire. Over time, this minor error becomes a major fault—resulting in jerky motion, unusual noises, or total failure.

Another critical point is anchoring and cable routing. The barrier should be securely bolted into the floor to handle user impact and vibration. Electrical and data cables must be routed safely to avoid damage from movement or cleaning. If these details are overlooked, you’re setting the system up for damage.

Manufacturers often provide installation guides or offer onsite setup services. Choosing a vendor who includes professional installation can make a big difference. They know the product best and can ensure everything is configured for optimal performance. This includes fine-tuning the opening speed, flap tension, and sensor thresholds.

Maintenance access also matters. If the barrier is installed too close to a wall or column, technicians may not be able to service internal parts. That makes every repair more time-consuming and costly. Good placement ensures the unit can be serviced quickly, without requiring complete removal.

Maintenance Requirements and Service Cycles

No barrier system is maintenance-free, but some are much easier to manage than others. Understanding maintenance requirements is a key part of choosing a durable flap barrier. The fewer interventions a unit needs—and the easier those interventions are—the longer and more cost-effective your system will be.

Start by reviewing the recommended maintenance cycle. Most high-quality barriers need a light service every 3 to 6 months. This includes checking the flap alignment, cleaning sensors, inspecting bearings, and testing the motor function. If the barrier needs constant lubrication or frequent part replacement, that’s a red flag.

Look for systems with self-diagnostics. These can alert your team to potential issues before they turn into failures. Smart sensors might detect increased motor resistance or sensor blockage and send a warning. That kind of foresight lets you fix small problems without causing entry delays or user frustration.

The design should also allow for easy access to serviceable parts. Some models require disassembling the entire frame to reach a minor component. Others offer hinged covers, slide-out motors, or detachable flaps that can be serviced quickly. Ease of maintenance saves time and labor costs—especially in busy facilities where every minute counts.

Durability also depends on the availability of spare parts. Stick with manufacturers who maintain strong supply chains and offer long-term part support. It’s not just about having the parts—it’s about getting them fast when you need them.

Proper maintenance doesn’t just preserve the barrier—it enhances safety, improves performance, and protects your investment. When evaluating flap barrier specifications, always consider what it will take to keep that system running at its best.

Performance Under Variable Conditions

Environmental conditions have a direct effect on flap barrier durability. If your site faces high humidity, fluctuating temperatures, or constant dust, you’ll need a barrier designed to handle it. Otherwise, you risk malfunctions, premature wear, or even safety issues.

Temperature extremes can affect motor function and material performance. In cold weather, standard flaps may become brittle. In high heat, motors can overheat and reduce their lifespan. That’s why some barriers include built-in heating or cooling systems, allowing them to perform in extreme environments. These systems help stabilize internal temperatures and maintain normal operation.

Humidity is another factor. In wet climates or facilities like pools, spas, or food plants, moisture can enter unsealed components and cause electrical shorts or metal corrosion. Systems with higher IP ratings and sealed electronics resist this damage.

Dusty environments like construction zones, factories, or open public transit hubs also require enhanced filtration and protection. Even fine particles can interfere with sensors, motors, and internal circuitry if the housing isn’t properly sealed.

Then there’s the matter of vibration and shock. Barriers near heavy machinery or train tracks may experience constant micro-vibrations. These wear down fasteners, loosen joints, and slowly degrade structural integrity. Barriers built for these conditions will feature vibration-resistant mounting and more robust internal connections.

So when evaluating flap barrier durability, match the system to your real-world conditions. A high-performance unit in the wrong environment won’t last. But a model designed for those challenges will keep working—no matter what nature throws at it.

Vendor Quality Assurance

Durability doesn’t just come from the barrier—it comes from the people who build and support it. A reliable vendor is key to ensuring that your flap barrier lives up to its performance claims. That’s why vendor quality assurance is one of the most critical durability factors.

First, consider the manufacturer’s reputation. Companies that have been in the industry for years usually have more refined production processes and better customer feedback. Look for reviews, case studies, and client references. If a vendor can show real-world success across different industries, that’s a strong sign their products are made to last.

Another clue to quality is the vendor’s warranty policy. A short or unclear warranty suggests the product may not be built for long-term use. A strong warranty—typically two years or more—demonstrates that the manufacturer stands behind their product. Some even offer extended service plans or support packages, giving you confidence that help is available when needed.

Also ask about spare parts availability. Can you get replacement motors, flaps, or circuit boards easily? How long will they continue to support your specific model? Reliable vendors maintain inventory for several years and often have local service partners to reduce response time.

For an added layer of trust, look into whether the vendor offers a quality control certification or manufacturing audit. These documents prove that the factory operates under strict standards and every unit is tested before shipping. You can get an idea of these practices by exploring their flap barrier quality check page, where inspection routines and product test results are shared.

Ultimately, even the most durable materials can fail if they’re poorly assembled or unsupported. A dependable vendor ensures the product you receive meets its spec sheet—and continues to perform for years.

Comparison of Durable vs. Standard Models

When weighing options, you’ll notice a wide gap in pricing between standard and heavy-duty flap barriers. Understanding the long-term value of each model helps you make a smart investment—not just a cheap one. Durable barriers cost more upfront, but they typically cost less over their lifespan.

Standard models often use thinner materials, simpler motors, and basic sealing. They’re fine for light-duty environments, such as office interiors with low foot traffic. But when exposed to high use or tough conditions, they wear down faster. You’ll spend more on repairs, replacement parts, and downtime.

Durable models, in contrast, are built to withstand stress. They use thicker stainless steel, better sealing, and industrial-grade motors. They may also include advanced diagnostics, IP65 environmental protection, and high-cycle mechanisms. These features reduce wear, prevent failures, and increase the time between maintenance cycles.

Think of it like comparing a basic commuter bike to a mountain bike. They may both have wheels, but only one is designed to handle tough terrain. The same logic applies to flap barriers. If your facility handles hundreds or thousands of users daily—or if it’s exposed to the elements—standard models will fail prematurely.

Durability adds long-term ROI. You’ll avoid frequent repairs, reduce replacement frequency, and minimize operational disruptions. Yes, you pay more upfront—but you get a system that pays you back in uptime, reliability, and peace of mind.

Use detailed comparisons like the flap barrier performance resource to evaluate what’s truly worth your investment. In security, as in most infrastructure decisions, cheap now often means expensive later.

Case Examples from Real Facilities

Facility managers across different sectors have already experienced the gap between durable and weak barriers. Their stories provide practical insight into what actually works long-term—and what fails under pressure.

One property manager at a metro station in Southeast Asia reported installing a low-cost model in a busy corridor. Within months, the flaps started wobbling, the motors overheated, and the system required daily technician visits. Eventually, the entire system was replaced with a high-durability model using IP65-rated housing and reinforced frames. Since the switch, the station has seen nearly zero unplanned downtime.

A university campus in Europe chose mid-range barriers for student access points. While the price was right, the barriers could not handle peak hour surges. Flap alignment issues led to sensors failing, which caused false alarms and user frustration. After consulting with the vendor and upgrading to models rated for 10 million cycles, the issues were resolved—and maintenance calls dropped by over 60%.

In contrast, a corporate headquarters in the U.S. invested in top-tier barriers from the start. The systems used 316 stainless steel, had motor redundancy, and were installed with proper grounding and alignment. Five years in, the units still operate like new, with only routine servicing required.

These examples show that while upfront costs differ, durability pays off in every environment. Whether it’s minimizing user disruption or extending product lifespan, the long-term savings and reliability of a durable system always outweigh the cost of a cheaper one that fails early.

Conclusion: Smarter Buying Through Durability Insights

Flap barrier durability is not just a nice-to-have—it’s the foundation of reliable access control. From material strength and motor quality to corrosion resistance and environmental protection, every factor plays a role in how long your system will perform. Understanding these details helps you avoid systems that break down early, cost more to maintain, and frustrate your users.

If you want a flap barrier that lasts, don’t just look at the price tag. Look at what’s under the hood. Look at the testing, the specs, the materials, and the vendor’s track record. Match the product to your real-world needs, and you’ll get performance that pays off year after year.

This guide has walked you through every key factor to consider. Now you have the knowledge to make a smart, confident choice. Choose durability—and you’re choosing peace of mind.